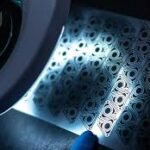

3D Laser Engraving Have you ever wondered how intricate designs and textures are created on various surfaces, from metal to wood? One of the most fascinating and precise methods is 3D laser engraving.

| Feature | Description |

| Definition | A technology that uses a focused laser beam to remove material from a surface to create a three-dimensional effect. |

| Process | 1. Design: A 3D design file is created. <br> 2. Laser Focus: A powerful laser is focused on the material. <br> 3. Material Removal: The laser vaporizes or melts material. <br> 4. 3D Structure: The final result is a 3D structure or engraving. |

| Applications | – Industrial manufacturing <br> – Medical field <br> – Art and crafts <br> – Prototyping |

| Benefits | – Precision and accuracy <br> – Versatility <br> – Speed and efficiency <br> – Customization |

What is 3D Laser Engraving?

3D laser engraving is a technology that uses a focused laser beam to remove material from a surface, creating a three-dimensional effect. It goes beyond traditional 2D laser engraving, which only creates flat images.

How Does it Work?

- Design: The process starts with a 3D design file, often created using computer-aided design (CAD) software. This file contains instructions for the laser to follow, specifying the depth and shape of each cut or engraving.

- Laser Focus: A powerful laser is focused on the material, precisely removing layers to achieve the desired 3D shape. The laser’s intensity and duration are carefully controlled to create the desired depth and smoothness.

- Material Removal: The laser beam interacts with the material, causing it to vaporize or melt away. The removed material is either ejected as a gas or collected as a fine powder.

- 3D Structure: The final result is a 3D structure or engraving that faithfully replicates the original design. The level of detail and precision that can be achieved is remarkable.

Applications

3D laser engraving has a wide range of applications across various industries:

- Industrial Manufacturing:

- Creating intricate molds and dies for manufacturing processes

- Producing precise components for machinery and electronics

- Customizing industrial tools and equipment

- Medical Field:

- Manufacturing implants and prosthetics with personalized shapes and sizes

- Creating surgical guides for precise procedures

- Producing custom hearing aids and dental appliances

- Art and Crafts:

- Creating unique sculptures and decorative pieces

- Personalizing jewelry and accessories

- Adding intricate details to wood, metal, and other materials

- Prototyping:

- Quickly creating prototypes of new designs and products

- Testing and refining designs before mass production

Benefits of 3D Laser Engraving

- Precision and Accuracy: The laser’s focused beam allows for highly precise and accurate engravings.

- Versatility: 3D laser engraving can be used on a wide range of materials, including metals, plastics, wood, and even glass.

- Speed and Efficiency: The process is relatively fast and efficient, especially compared to traditional methods.

- Customization: 3D laser engraving allows for complete customization, enabling the creation of unique and personalized items.

In Conclusion

3D laser engraving is a revolutionary technology that is transforming the way we create and manufacture products. Its precision, versatility, and speed make it a valuable tool for industries ranging from manufacturing to art and design. As technology continues to advance, we can expect even more innovative applications of 3D laser engraving in the future.